All Yamada Air Powered Double Diaphragm Pumps feature bolted body construction, which eliminates leaks and simplifies post-maintenance reassembly. Bolted construction is generally superior to clamp band retainers, which frequently require frustrating, unnecessary leakage rebuilds from misalignment during reassembly.

Features:

One of the more difficult tasks in selecting a pump for long, trouble free service is the proper choice of both wetted and non-wetted pump components. Pump components wear, and the objective is to get the longest life from the wearing parts. Knowing how to han-dle abrasive and corrosive fluids will lead to proper wetted materials selection. When selecting a pump for corrosive service most use chemical compatibility charts and graphs for selecting and recommending pump materials of construction. These charts; at best, are meant as ever so general guidelines. Practical experience, and past history will dictate the use of certain materials with various fluids.

Document download

Pump components wear, and the objective is to get the longest life from the wearing parts. The downloadable guide will assist you in identifying the cause of diaphragm failure and possible solutions for modifying the elastomer selection or operational conditions to improve elastomer life.

Document download

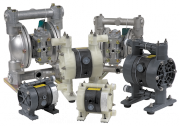

Yamada Air-Powered Double Diaphragm Pumps have distinct design advantages that make them very versatile and cost effective drum pumps.Models are available in Polypropylene, PVDF (Kynar®), Aluminum, and Stainless Steel which includes a 2" bung adapter and 33" suction tube.

The Yamada Engineering Handbook combines AODD operation and selection data sheets into an understandable and convenient information source, to enable the end user to select the correct pump for their application.

Document download

Yamada Powder Pumps were specifically designed to move bulk solids more effectively throughout your process. They are a cost effective replacement for Augers and Conveyors and eliminate unsafe and labour intensive means of moving bulk powders. These heavy duty pumps consistently transfer fine-grained (100um or finer), low bulk density (5 to 50 lbs. / cubic foot), dry powders in a dust-free operation.

Document download